I would match what you get from your paste supplier and get the flux from them. It probably wouldn't hurt to throw on additional flux on the board before you put it in the oven, I wouldn't spray it as this would leave a no-clean residue over the board. I would throw a thermocouple and see if you can measure it.

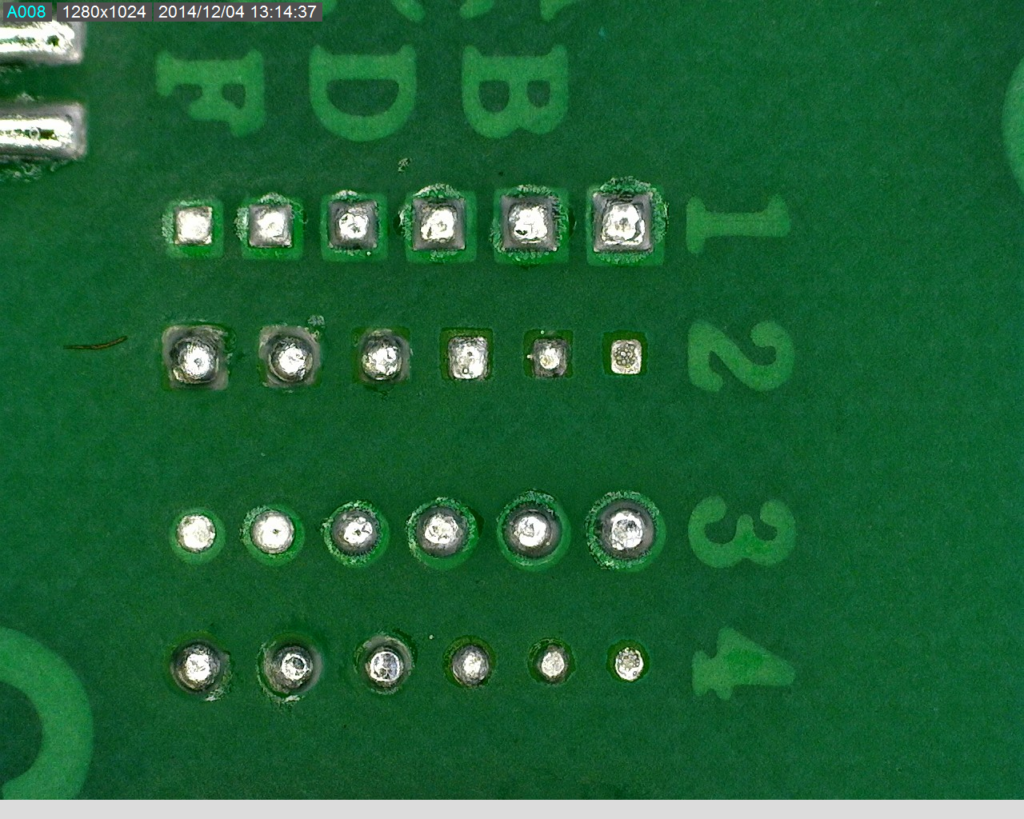

We however do not have problems as you described above, I'm willing to bet that your temperature profile is not as hot as it needs to be. This leaves the flux on the board to evaporate for hours. However, I do my own prototyping and the larger boards sometimes take an entire day just to stuff all the parts. Typically there might not be enough wetting and the solder doesn't flow as well. The flux does evaporate and it can affect the solderabilty of the board. Should I spray some flux onto the board before I shift it into the reflow oven? If yes, what spray would you recommend? But that doesn't happen.Īnother example: Imagine some solder paste that isn't applied very good:ĭuring the reflow process, I would expect it to flow like this - as if it is attracted to the copper pads and repulsed by the naked FR4-material or coatings(where no copper is present): For example, I would expect slightly misaligned resistors and capacitors to straighten up when the solder melts. I've got the impression that the solderpaste doesn't "flow" sufficiently. It generally takes several hours - up to 8 hours for my latest PCB - to get all components in place. However, I'm worried the flux evaporates while I'm placing the components. Next, I place all the components one-by-one. I use a stencil to apply the solderpaste. I am using Tin-Lead solderpaste to make my prototype circuits.

0 kommentar(er)

0 kommentar(er)